Over 5000 Fluid Applicators and Counting…

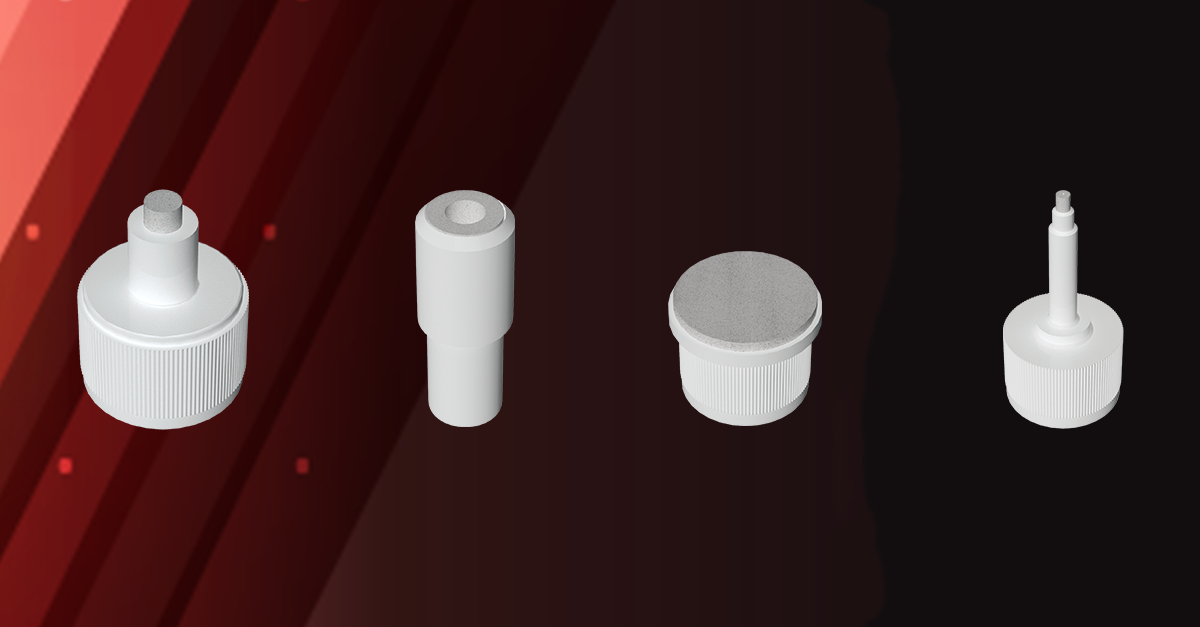

Our standard offerings span a wide range of applicator geometries and media – from traditional applicator brushes and channel applicators to round, flat, and wraparound designs. And we have a broad selection of materials in stock that work with virtually any fluid and substrate.

In fact, Designetics is a vertically integrated, U.S. manufacturer. All of our fluid applicators are made in-house at our Holland, OH facility – so we have control over the entire process. This gives us the ultimate flexibility to design exactly the right applicator for your needs, and to do so with quick turn-around times, whether for prototyping or production volumes.

Wraparound applicators are used when fluid needs to be applied to multiple sides of a substrate. For example, when mounting rubber trim to glass, primer is needed on the top and bottom surfaces and the side edge of the glass. A wraparound applicator makes it possible to coat all three surfaces with one stroke.

There’s Always Room for One More

When designing a custom fluid applicator, we look at all aspects of the process – the chemical and substrate, required dimensions and accuracy, whether the application will be hand-held, semi-automated, or fully automated, and any unique challenges the customer is facing. Each applicator solution is carefully thought-out using our six-step process:

- Listen to the customer’s needs and challenges

- Understand the customer’s manufacturing process

- Determine if an existing fluid applicator is the best solution, or if a custom design is better.

- Test potential applicators and designs with the specific material and substrate, to evaluate their performance.

- Fully replicate the customer’s process in our shop, to accurately test and validate the chosen applicator or design.

- Test the chosen applicator at your facility to ensure performance matches our expectations and your goals.

Our portfolio includes over 5000 applicators, but if your applicating process requires a custom design, our engineers are experts in fluid application and can work with you to design the best solution for your process.

Fluid Applicators Tailored to Your Needs

Each fluid applicator that we design is tailored to the customer’s specific need, whether it’s a channel-type applicator to coat the inside of a part, a flat applicator with a guide to ensure proper placement and high accuracy fluid delivery, or a new shape specific to your substrate. And we’ve tested dozens of applicator materials – from felt and synthetic hair to foam rubber and goat hair – with all types of fluids, with the ability to source and test new materials if the need arises.

Round applicators are ideal for automated systems since they don’t require a special sequence or sensor to ensure they’re properly oriented with the robot’s end-of-arm tool and the substrate.

Fluid Applicator Prototyping Available

We even offer a prototyping service that you can initiate online, via a simple prototype request form. Just fill out the form with info including the name of the chemical and the basic applicator dimensions, and our expert team of engineers will design a prototype applicator tailored to your needs. And if modifications are needed, we’ll work with you throughout the process – from design and testing through production.

At Designetics, we are THE applicating authority, with a portfolio of over 5000 fluid applicators. But we’re not trying to fit a square peg into a round hole, so to speak. We have the expertise and experience to design and manufacture custom applicators from scratch to meet your exact fluid application needs. To get started with the prototyping process for a custom-built fluid applicator, check out our online prototyping request, or give us a call.