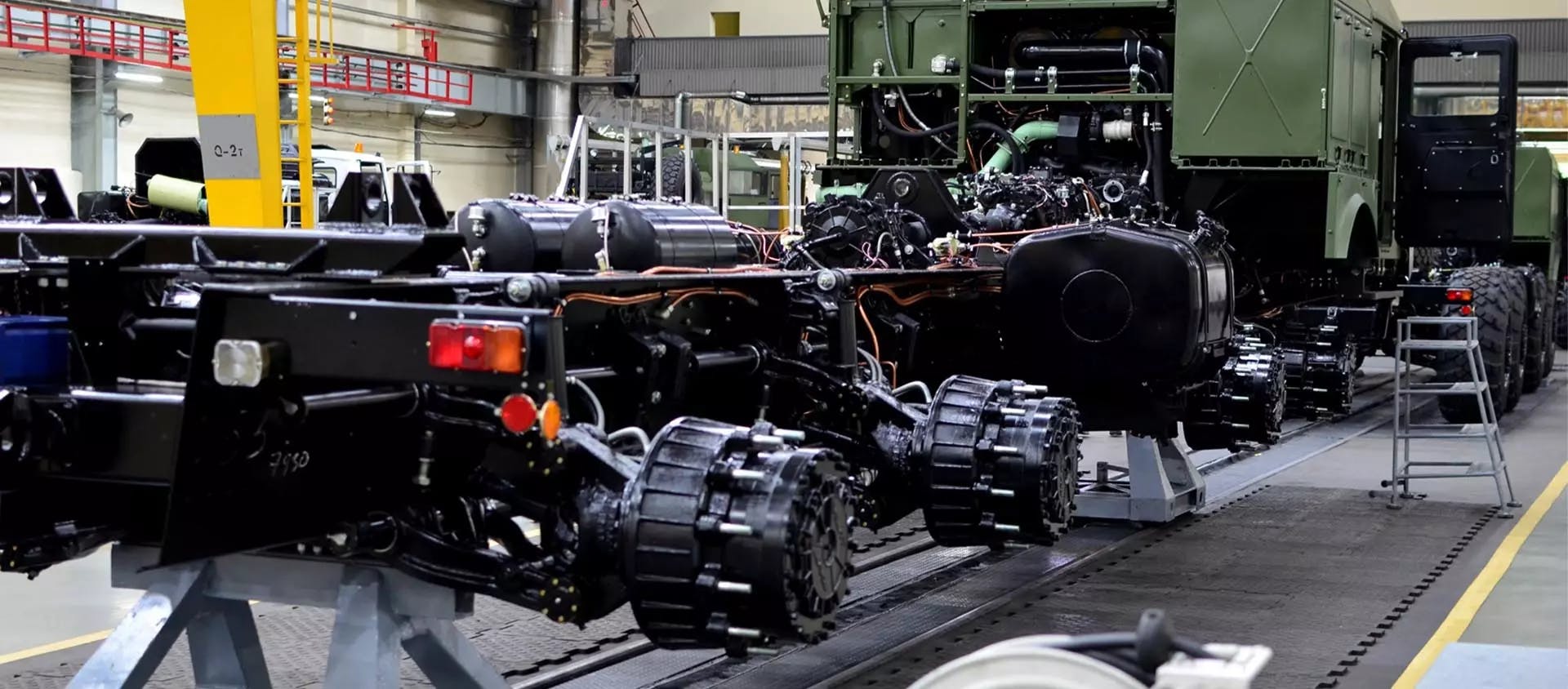

Scaling Production With Quality and Precision

Defense Fluid Dispensing Solutions

The defense manufacturing sector faces a rapidly evolving landscape, with fierce competition and demanding standards. Ensuring precision, cost-efficiency, and impeccable quality is paramount to navigating this challenging terrain. As the global frontrunner in fluid application solutions, Designetics® empowers defense manufacturers with cutting-edge equipment and applicators tailored to meet these exacting demands.

How Fluid Dispensing Systems Increase Quality

Precision fluid dispensing systems play a crucial role in enhancing the quality and lifespan of defense products. By ensuring accurate and consistent application of adhesives, lubricants, and other critical fluids, these systems minimize material waste, reduce manufacturing errors, and prevent common issues like improper bonding or sealant failures. This results in stronger, more reliable defense components that meet or exceed rigorous industry standards.

Incorporating automated fluid dispensing also helps streamline production processes, leading to increased throughput without compromising on precision. This high level of accuracy ensures compliance with defense manufacturing specifications, improving overall product performance and operational longevity.

Systems for Defense Fluid Dispensing

Our precision fluid dispensing systems are designed to optimize the defense manufacturing process. They ensure the accurate application of critical fluids, improving product performance and enhancing the durability of each component. Whether used in adhesive application or anti-corrosion treatment, our systems guarantee the reliability and long-term operational success of defense products.

AUTOPRIME® CE

The AUTOPRIME system offers automated fluid dispensing with advanced priming capabilities, ideal for high-volume defense production. It optimizes fluid delivery, reducing downtime and improving overall manufacturing efficiency.

e3mini®

The e3mini system provides highly precise fluid application, ideal for intricate or small defense components. Its compact design ensures efficient material usage while adhering to strict specifications, making it perfect for environments where space and precision are critical.

e3minimax®

The e3minimax system offers flexibility in handling various fluid viscosities, delivering consistent, high-precision application across a wide range of defense manufacturing processes. This system is particularly suited for large-scale operations requiring accuracy and adaptability.

e3multi®

The e3multi system excels in multi-fluid environments, where the need for handling various types of fluids is essential. It delivers unmatched precision, making it a key asset for defense manufacturers working with complex, multifaceted applications.

Custom Fluid Applicators

The unique requirements of defense manufacturing often necessitate tailored solutions. Recognizing this, Designetics harnesses the power of rapid prototyping and 3D printing to craft custom applicators that align perfectly with specific needs. Beyond our bespoke solutions, we also boast a vast range of off-the-shelf fluid dispensing applicators, ensuring defense manufacturers have the tools they need to excel.

Defense Fluid Dispensing Product Applications

Glass Substrates

Ensure impeccable bonding and sealing on glass components, a crucial element in many defense instruments. Our equipment ensures precision and consistency, vital for the high-stakes defense sector.

Plastic Components

Plastic components in defense equipment demand accuracy and durability. Designetics’ applicators guarantee flawless adhesive applications, maximizing the lifespan and functionality of these components.

Anti-Corrosion

Corrosion can be a silent assailant in defense tools. Our dispensing solutions meticulously apply anti-corrosive agents, safeguarding equipment from environmental adversities and ensuring long-term reliability.

Lubrication

Smooth operation is non-negotiable in defense mechanisms. Our fluid applicators ensure precise lubrication, promoting optimal functionality and minimizing wear and tear.

Sub-Assembly Processes

Every sub-component in defense equipment plays a vital role. Our fluid dispensing solutions ensure each part is meticulously prepped and assembled, contributing to the overarching efficiency and dependability of the final product.

Increase Precision and Quality While Improving Cost-Efficiency Today!

Start A ConversationFrequently Asked Questions

Are your fluid dispensing systems compatible with defense-grade materials and requirements?

Yes, our systems are specifically designed to be compatible with defense-grade materials, meeting the rigorous standards required in the defense industry. We ensure that all materials used in our systems can withstand the specific demands and conditions of defense manufacturing, from extreme temperatures to harsh environments.

Do you provide training for defense personnel on using your dispensing systems?

Absolutely. We offer comprehensive training programs tailored to the unique needs of your team. Our training ensures that your personnel are fully equipped to operate our dispensing systems efficiently and safely, maximizing the performance and longevity of the equipment.

Can your fluid dispensing systems accommodate the demands of high-volume defense production?

Yes, our fluid dispensing systems are designed to handle high-volume production demands without compromising precision or reliability. They are built to maintain consistent performance under continuous use, making them ideal for large-scale defense manufacturing projects.

Are your systems compliant with defense industry standards and regulations?

Yes, our systems meet all applicable defense industry standards and regulations. We regularly update our products and processes to comply with the latest standards, ensuring that we provide not only innovative but also fully compliant fluid dispensing solutions.