Preventing Applicator Equipment Downtime

Regardless of whether your fluid application process is manual or automated, downtime is inevitable. Depending on your production needs, your applicator may be out of use for a few minutes to several hours. During these periods, it is crucial to store your fluid applicators properly to prevent contamination, damage and drying out. Proper storage can help to ensure the longevity and optimal performance of your applicator. Designetics’ docking stations and precision compliance units integrate seamlessly with many of our fluid applicators to alleviate those concerns.

Our team understands that every fluid application system is unique. That’s why we employ a comprehensive exploration process designed to determine which dispensing system is the right fit.

What Leads to Ineffective Applicators

Contamination

Contamination of an applicator with dirt and dust, either from the production environment or substrate, can compromise the quality of the fluid flow. If the applicator is not cleaned properly, it will continue to contaminate subsequent parts as they move through production, causing slow-downs and restrarts. The impact of contamination on productivity can be significant, making it essential to check that your applicators are kept clean and well-maintained.

Damage

Depending on the type of applicator and substrate used, the applicator tip may degrade over time. It is important to monitor the condition of the tip regularly to ensure that it is functioning correctly and providing the desired results. When applicators begin to break down or abrade, they become deformed and lose their intended shape.

“Every millimeter makes a difference in fluid applications,” said Jeffrey Schnapp, Designetics’ regional sales manager. “The width of the applicator that comes in contact with the substrate is called the prime path. If your applicator becomes too wide or too narrow due to degradation, you’re no longer coating that prime path.”

Dry Out

Manufacturers face another challenge with applicator dry out. When a felt applicator is coated with fluid, the solvent evaporates quickly from the surface of the part. The ingredients then set up with air movement, temperature, and moisture, which is great for the surface of the part but bad for the applicator. According to Schnapp, “Once the applicator is dry, there’s no way to shake it off.”

A partially wet applicator can produce streaks during fluid application, leading to compromised quality. It is essential to ensure that the applicator remains adequately lubricated throughout the application process, as this can help to prevent dry out and minimize the risk of quality issues. Regular inspection of applicators and replacement of worn or damaged parts can also help to prevent dry out and prolong the life of the applicator.

How to Prevent Applicator Damage

To ensure a fluid applicator consistently performs accurately, manufacturers can implement docking stations and precision compliance units in their fluid application systems.

Docking Station

The Designetics docking station not only protects the applicator from contamination, damage, and dry-out but also facilitates the wet-out process for the applicator tip. To use the docking station, the user fills it with the chemical or base solvent to be dispensed. Once the fluid fills the applicator bottle and the applicator tip is mounted, the bottle is held upside down over the docking station. The user then squeezes the bottle until fluid flows through the applicator, completely wetting the tip. The docking station shields the applicator from damage and stores it head-down, ensuring that it remains fully lubricated.

According to Schnapp, “If you use any of our equipment options, you can choose to have the applicator wet-out at any interval or duration of your choice. We help you build a complete custom program that works specifically for your needs. With a docking station and pump system in place, you’ll determine a specified timeframe for the system to wet-out the applicator, ensuring it’s ready for the next application.”

Designetics provides the docking station as a standard accessory with both the Handheld Remote and Applicator Track, or it can be ordered individually. By incorporating the docking station into your manufacturing process, you can ensure that your applicators remain adequately lubricated and minimize the risk of contamination, damage, and dry out, ultimately improving the efficiency and quality of your production output.

Precision Air Compliance

Consistent pressure between the fluid applicator and substrate is crucial for uniform fluid application. Incorrect pressure or increased friction can cause applicator damage and negatively impact quality. Any time the applicator changes position due to deviations in the part, for example, the pressure level between the applicator and substrate will vary. To illustrate this, consider you and a friend drawing a line with brand new felt tip markers. If your friend were pushing down as hard as possible while you used normal writing pressure, your friend’s marker would wear out much faster.

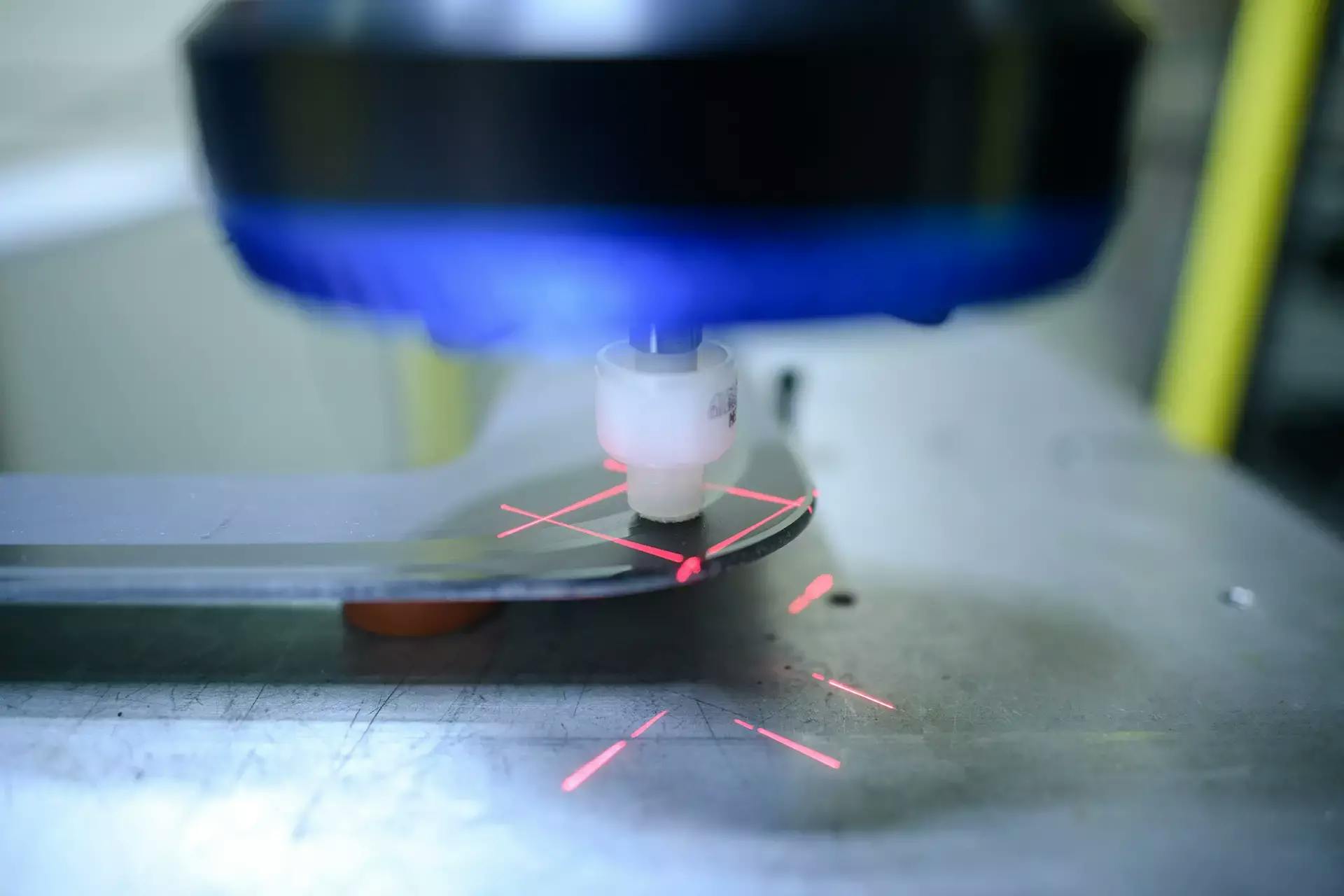

The Designetics Precision Air Compliance is an end-of-arm tool that maintains constant pressure between the applicator and substrate, regardless of deviations in the applicator’s position. The tool can be used on a robot or stationary machine. Two air regulators are set with a pressure differential to create a downward force on the applicator, while a float ensures the applicator “rides along” any variations in the substrate. This combination keeps fluid delivery consistent and reliable, ensuring high-quality output. By incorporating the Precision Air Compliance into your manufacturing process, you can help prevent applicator damage and minimize variations in fluid application, ultimately improving production efficiency and product quality.

Fluid Application Systems to Keep Your Applicators Operating

In conclusion, proper maintenance and care of fluid applicators can help maximize their longevity and efficiency, resulting in higher quality output and increased productivity. From preventing contamination and dry-out to facilitating the wet-out process and maintaining consistent pressure, Designetics offers a range of solutions to ensure your fluid applicators are operating at peak performance. By incorporating these techniques and equipment options into your manufacturing process, you can minimize downtime, reduce costs, and achieve the highest quality standards. Contact Designetics to learn more about how we can help improve your fluid application process and equipment efficiency.