How Quality Can Be Compromised in Fluid Application

There are many ways that quality can be compromised in fluid application – for example, too much fluid, too little fluid, or incorrect fluid placement. Designetics fluid applicators and automated systems are designed to minimize these issues, but quality and safety requirements, along with mandates for complete product traceability, make secondary inspection a necessary step for many manufacturers. But manual inspection can be subjective and inconsistent, and it takes operators away from other critical tasks. And vision camera inspection systems can be affected by ambient light and robot speed, producing “false-failures” that increase time, scrap, and cost. The Ce360 solves these problems, providing reliable, consistent, 3D quality inspection and recording of the fluid dispense path.

Precision Air Compliance + PrimerMaster Pro = A Quality Partnership

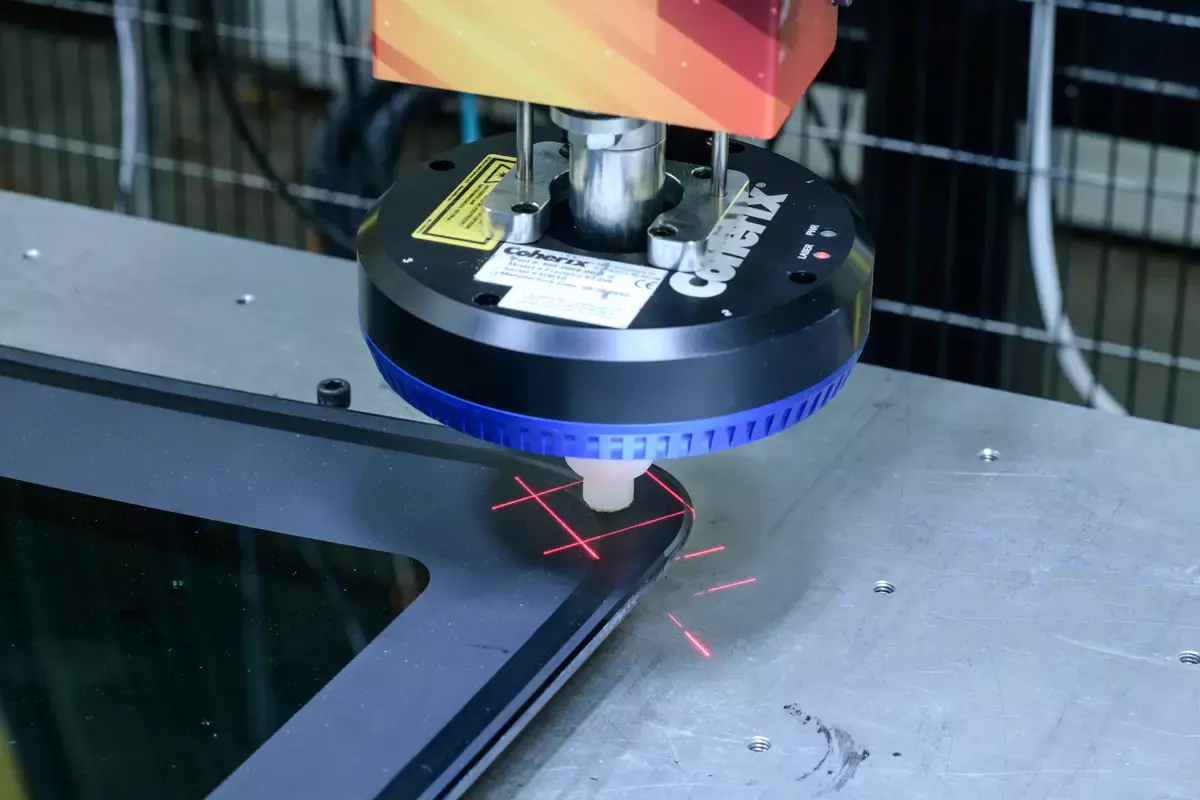

The Ce360 path scanner for quality inspection consists of a Coherix PrimerMaster Pro system mounted to Designetics Precision Air Compliance, for seamless integration with Designetics automated fluid application systems. Because it’s mounted to the shaft of the Precision Air Compliance, the PrimerMaster Pro is able to “float” along the substrate, maintaining a consistent distance from the surface and avoiding any distortions that might otherwise occur due to extreme changes in the Z (vertical) axis. And through our close partnership, Designetics and Coherix have ensured that the integration of the PrimerMaster Pro doesn’t interfere with any of the normal functionality of the Precision Air Compliance – including the “applicator strip” function.

The PrimerMaster Pro can process and record 1600 samples per second.

Maximizing Applicator Lifespan with the PrimerMaster Pro

The PrimerMaster Pro uses laser line triangulation for real-time inspection of the dispense path, with 4 laser lines and 400 samples per line, per second, to produce a total of 1600 samples each second. The user sets the width tolerance of the path (down to +/- 0.35 mm), and can also set a “marginal failure” point at which the scan passes but triggers an alert for the operator in case preventive maintenance is required. This feature also helps the operator track and maximize the life of the applicator – when the width of the fluid path reaches the marginal failure point, the operator can plan for a just in time applicator change-out.

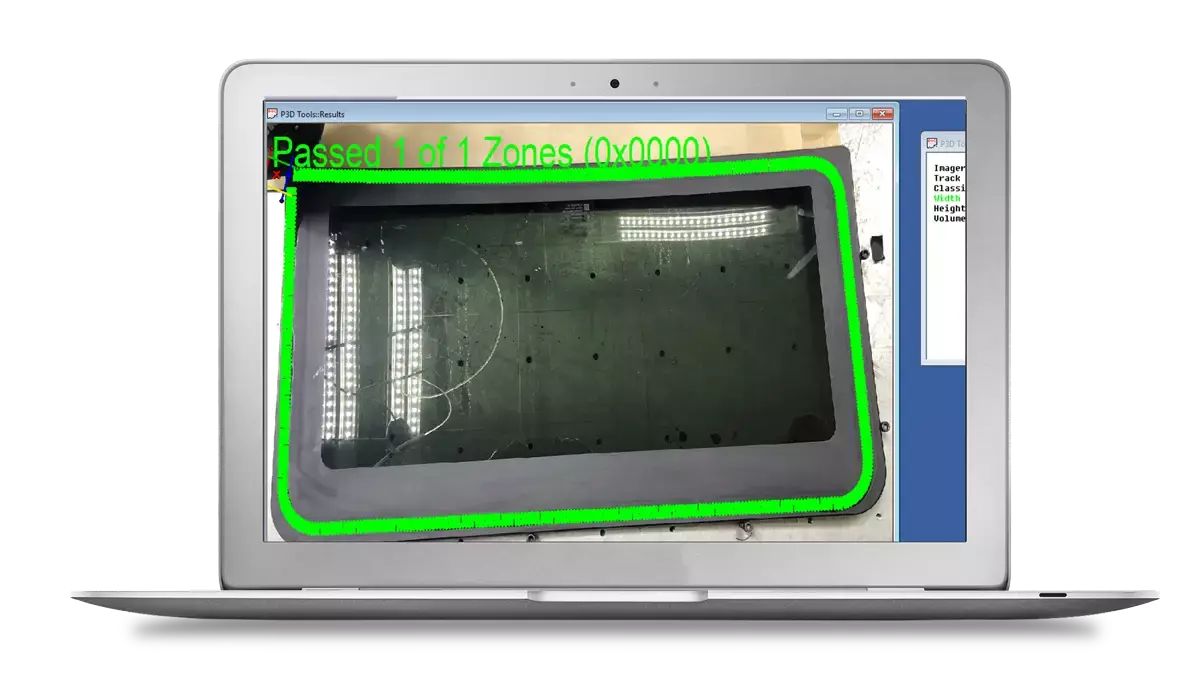

But the Ce360 isn’t just a “go/no-go” verification tool – it enables complete part traceability and supports Six Sigma quality tracking and reporting. With 1600 samples per second, the PrimerMaster Pro can provide a visual display of each dispense path, showing a success or failure for each scan. It can also provide the exact location and measured values of every failed scan on every part. And all of this data can be recorded for shift and lot number traceability.

The Ce360 provides a visual display of each dispense path, showing the exact location and measured values for each scan.

The new Ce360 path scanner for quality inspection from Designetics and Coherix provides real-time inspection of fluid application without slowing down the production process. And it reinforces our commitment to accuracy and quality, giving our customers a reliable solution for monitoring, inspecting, and tracing their critical fluid application processes. To learn more about the Ce360 and how it can improve your quality program and part traceability, contact us today.