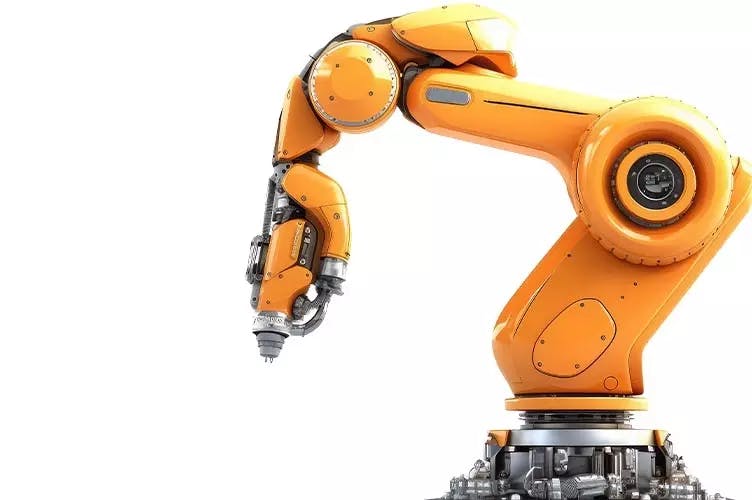

Industrial Automation Fluid Dispensing Solutions

In the rapidly evolving world of industrial manufacturing, precision, speed, and reliability are the bedrock of success. Industrial automation offers unprecedented efficiency and ensuring its effectiveness hinges on the quality and reliability of the equipment and tools employed. Designetics stands at the forefront of fluid application solutions, tailor-made for the demanding realm of industrial automation.

How Fluid Dispensing Solutions Improve Industrial Automation Efficiency

Fluid dispensing solutions enhance industrial automation by reducing manual labor, minimizing errors, and accelerating production cycles. By delivering precise and consistent amounts of fluid to critical areas, these systems improve manufacturing speed while maintaining high-quality standards, ensuring both cost-effectiveness and operational efficiency.

Industrial Automation Fluid Dispensing Systems

Our industrial automation fluid dispensing systems are designed to integrate seamlessly into automated manufacturing processes. These systems enable precise fluid application, reduce waste, and ensure consistent results, enhancing both the efficiency and quality of production in automated environments.

AUTOPRIME® CE

The AUTOPRIME CE system ensures high-efficiency fluid dispensing by automating the priming process, providing consistent fluid flow for uninterrupted, reliable application across various industrial automation applications.

e3mini®

Compact and precise, the e3mini is ideal for industrial automation fluid dispensing in tight spaces, offering exceptional accuracy for small-volume fluid applications while maintaining high reliability for automated systems.

e3minimax®

Versatile yet precise, the e3minimax is capable of handling a wide range of fluid viscosities, making it a flexible solution for diverse industrial automation applications while ensuring consistent and efficient dispensing.

e3multi®

The e3multi excels in multi-material fluid dispensing, offering seamless transitions between different fluid types for complex industrial automation processes, ensuring accurate and efficient applications for adhesives, sealants, and lubricants.

Customized Fluid Applicators for Industrial Automation

The uniqueness of every automation process requires tools tailored to its specific needs. Designetics rises to this challenge by offering customized fluid applicators, sculpted through rapid prototyping and 3D printing. Whether it's a nuanced requirement or an off-the-shelf solution from our extensive product range, we ensure that our tools seamlessly augment your automation process.

Industrial Automation Fluid Dispensing Product Applications

Glass Substrates

Achieve flawless bonding and coating on glass substrates, pivotal for many industrial products.

Plastic Components

Ensure impeccable adhesive application for plastic components, promoting durability and structural cohesion.

Extrusion Processes

Our fluid application tools streamline extrusion processes, enhancing product uniformity and quality.

Eliminates Buzzing, Squeaking & Rattling

Redefining precision, our solutions proficiently counteract common industrial nuisances, ensuring an impeccable end product.

Anti-Corrosion

Protect your products from environmental factors. Our fluid dispensing solutions bolster anti-corrosion properties, extending the product’s lifespan.

Lubrication

Maintain the smooth functioning of automated machinery through precise and consistent lubrication application.

Sub-Assembly Processes

Enhance the efficiency of sub-assembly processes with our meticulously designed fluid applicators, ensuring every component fits perfectly.