Speed Up Production with Automated Dispensing Equipment

Additionally, by employing Designetics’ automated dispensing equipment, assembly line workers can speed up production. This time savings can then mean reallocation of resources or increased production.

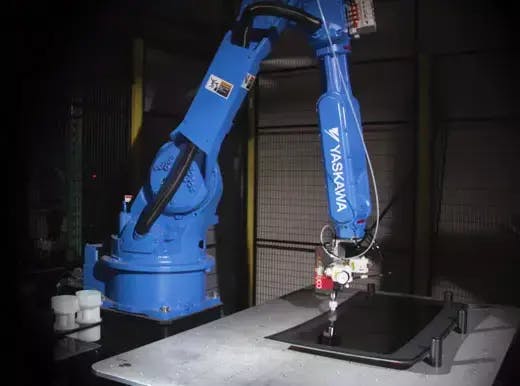

And, there’s the potential for automation. By using Designetics-based automated solutions, manufacturers can reduce costs via robotics or fully-integrated systems. This can help manufacturers weather market volatility. What’s more, Designetics engineers and staff can work with manufacturers to determine if more cost and time savings can be implemented with Designetics products.