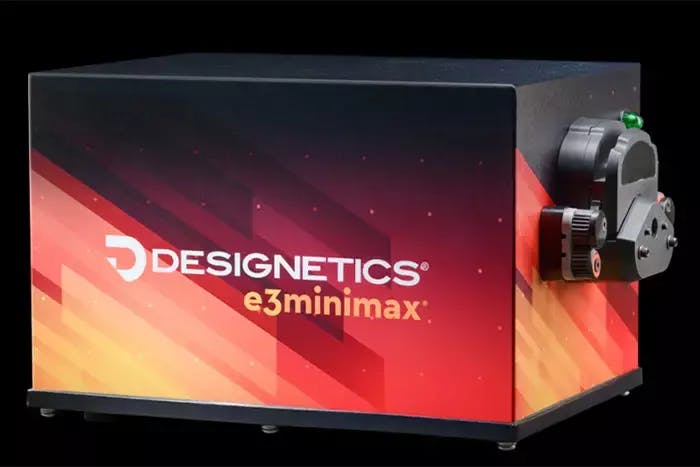

Capabilities of the e3minimax

The e3minimax is engineered with a robust set of features that enhance the efficiency and precision of fluid dispensing, positioning it as a top-tier solution for diverse application needs. Its design streamlines the dispensing process, offering users both reliability and advanced control in their operations.

A Servo-Driven Pump for Precise Applications

At the heart of the e3minimax is a servo-driven peristaltic pump, celebrated for its exceptional precision. Fluids are gently transported through the system without contact with mechanical parts, mitigating contamination risks and maintenance needs. The servo motor provides real-time feedback, ensuring fluid application remains consistent at any speed, translating to higher quality, minimal waste and increased production efficiency. This level of accuracy is indispensable for sectors requiring meticulous fluid control.

Automation for Efficiency

The e3minimax propels fluid dispensing into a new era of efficiency through automation. By integrating with robotic systems and machine automation via fast, reliable Ethernet communication, it not only reduces manual labor but also minimizes the chance of human error. This intelligent system’s automation capabilities help confirm that tasks are performed consistently and quickly, leading to streamlined operations and enhanced productivity.

Advanced Control & Programming

Beyond automation, the e3minimax offers intuitive control and programming options. With Ethernet/IP or Modbus TCP communication protocols, the system boasts fast and intelligent interaction with master controllers. These advanced features allow users to fine-tune dispensing parameters with precision, allowing fast, responsive and smart fluid dispensing for any application.

User-Friendly Interface

Despite its advanced capabilities, the e3minimax maintains a user-friendly interface. Configuration is accessible via a web-based platform, eliminating the need for complex HMI panels. This simple design enables operators of varying skill levels to manage the system with ease, further democratizing high-precision fluid application.

Industry-Specific Applications

The e3minimax system is versatile enough to cater to a variety of industry requirements, with each benefitting from its precision and reliability:

- In Electronics manufacturing, it is instrumental for the exact placement of adhesives and coatings, safeguarding delicate circuitry and enhancing product longevity.

- For the Automotive sector, the system’s ability to apply sealants with consistent thickness and width is critical for ensuring the durability and safety of vehicle components.

- Aerospace industry professionals rely on the e3minimax for the meticulous application of fluids that are essential to maintaining the integrity of flight-critical components under extreme conditions.

- Medical Device manufacturing depends on the system for its precise dispensing capabilities, making sure that sensitive medical instruments receive the correct amount of adhesive or coating in a sterile process.

- For the Consumer Goods industry, the e3minimax offers precise dispensing for products ranging from household appliances to personal care items, ensuring strong bonds and quality assembly while maintaining high production rates.

Support & Training

Adopting the e3minimax comes with comprehensive support and training from Designetics. Our experts provide guidance to ensure users can fully leverage the system’s capabilities. With customized training sessions and resource availability, clients are equipped with the knowledge and skills to optimize their fluid application processes.

Key Takeaways

The e3minimax by Designetics is more than an automated fluid dispensing system—it’s a step forward in production efficiency and accuracy. It’s designed to integrate seamlessly with existing automation, minimize waste, and enhance product quality, all while being accessible through a user-friendly interface. With its diverse industry applications and backed by expert support, the e3minimax is the forward-thinking choice for businesses aiming to excel in fluid application processes. Discover how the e3minimax can transform your operations by visiting the Designetics website or reaching out to our team.