We Control our Process So You Can Focus on Yours

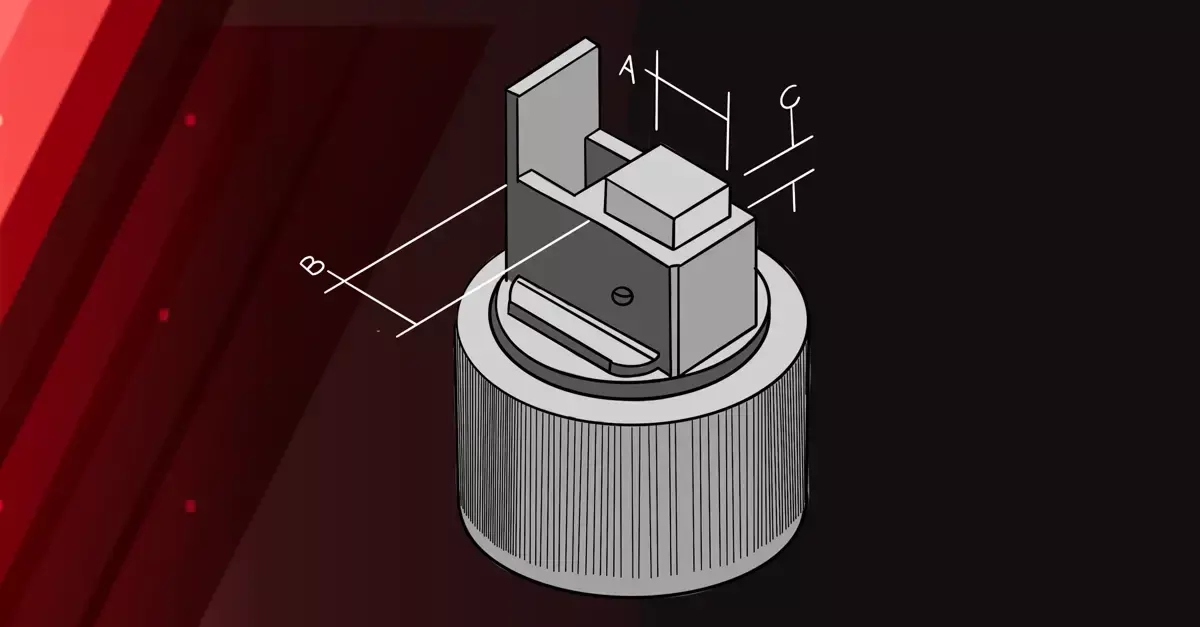

One of the ways we do this is through vertical integration. All of our fluid applicators are manufactured in-house at our Holland, OH facility – from designing the molds for applicator bases to choosing the best material for your fluid and substrate – vertical integration gives us the flexibility to design exactly the right applicator for your needs and provide fast turn-around times, whether for prototypes or production volumes.

Whether for prototype or production volumes, vertical integration gives us the flexibility to design and deliver an applicator solution that exactly meets your needs.

By controlling the entire process, we can ensure the quality and performance of every fluid applicator – and fluid application system – that we deliver is exactly what you expect from the leader in fluid application solutions. And we can help you get your production started even faster, whether you’re prototyping a new process or going into full production. With Designetics, you get exactly the solution you need, when you need it.

Go Ahead – Request Away!

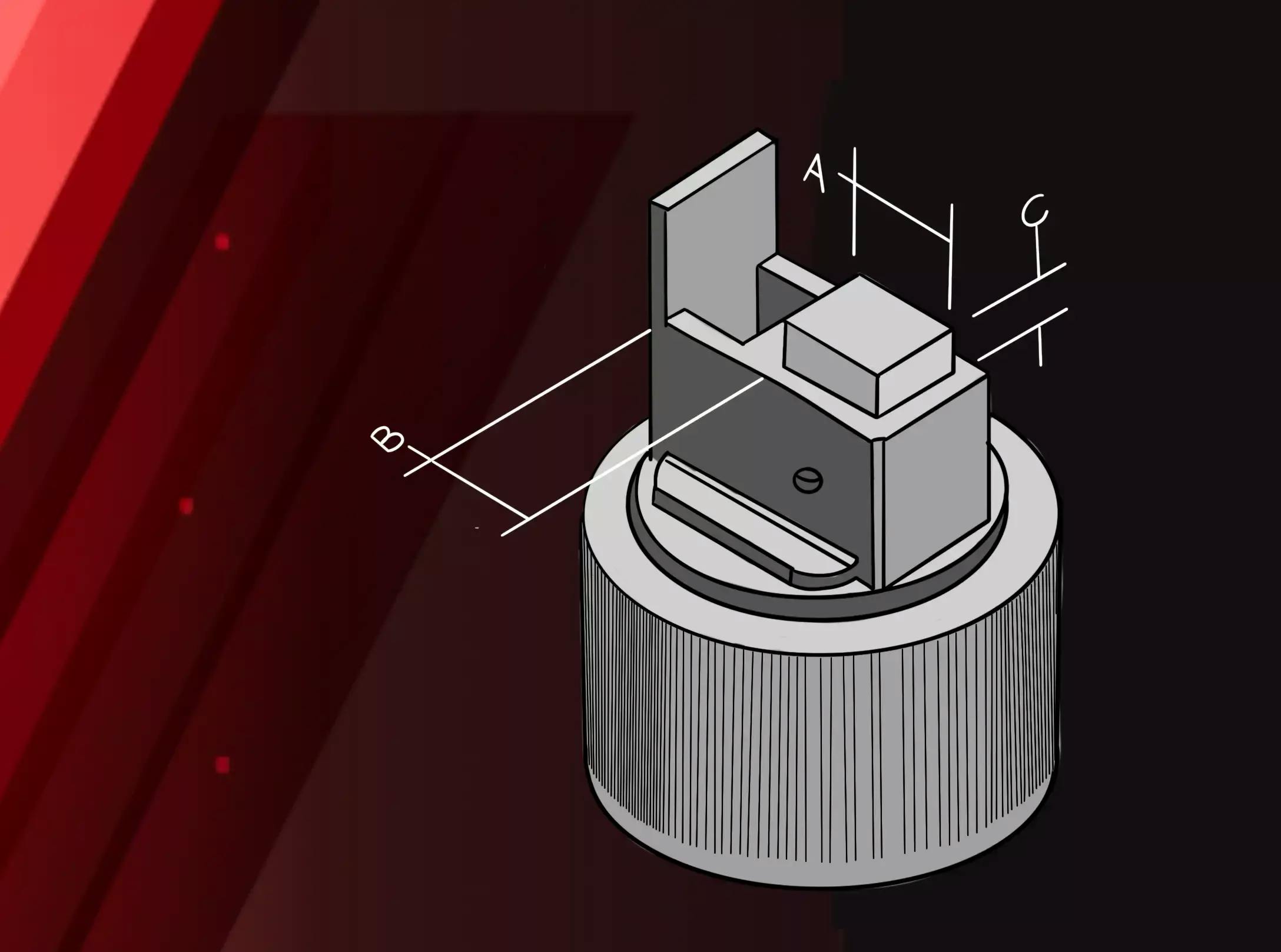

In fact, our prototype request form was developed to streamline the initial steps in the prototyping process and get parts to our customers even faster. Filling out the prototype request form is simple – just provide the name of the chemical, the type of applicator you need, and the basic applicator dimensions, along with any additional notes or drawings that would be helpful. Then our engineering team will take your requirements and determine the best applicator for your process – whether it’s one of our existing applicators, a modified version of an existing applicator, or a completely new design.

The Power of Fluid Applicator Prototypes

If a new or modified applicator design is needed – no worries. Designetics can provide prototypes within days – not weeks – thanks to our rapid prototyping program. Being vertically integrated means we rarely have to source new materials for your prototypes – even for completely new designs. And our internal R&D team uses their experience in manufacturing processes and fluid application to develop the best applicator solution – one that exceeds your expectations for accuracy, ease-of-use, and quality.

Requesting a prototype applicator is simple with our prototype request form. Just provide the name of the chemical, the type of applicator you need, and the basic applicator dimensions, along with any additional notes or drawings that would be helpful, and we’ll get to work developing the right applicator for your process.

Once we create the applicator design and choose the materials, if a new base design is required, we use state-of-the-art 3D printing to develop a prototype that is durable and resistant to most chemicals. Then we assemble the prototype applicator in-house and deliver it to you – all within a matter of days, so you can do real-world testing and move to production as quickly as possible. Throughout the prototyping process, if modifications are needed, we work with you to get the perfect applicator nailed down and get you on your way to full production.

Whether Prototype or Production Units, We’ve Got You Covered

We developed our rapid prototyping program so that our customers can get to the “real-world” testing phase much quicker. But we were careful not to cut corners or compromise on quality. With Designetics, we give every customer and every application our full attention – from choosing the right applicator design and materials, to ensuring that our prototype parts meet our highest quality standards. Because ultimately, our success hinges on your success.

With our combination of experience, vertical integration, and flexibility, you can be sure you’ll get a fluid applicator that exactly meets your needs – whether it’s a prototype to test on a new process or a production unit. To request a new fluid applicator design, check out our prototype request form, or give us a call.