April 8, 2024

Enhancing Precision with Automated Fluid Dispensing Systems

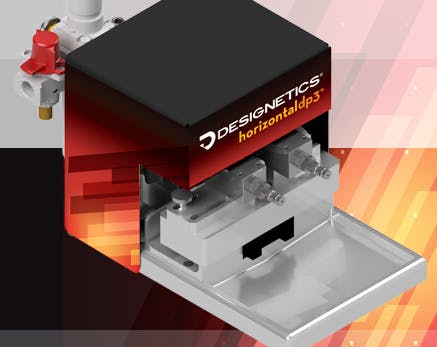

In the manufacturing and production landscape, achieving precision in fluid dispensing processes is fundamental for securing high-quality results across industries. The advent of automated fluid dispensing systems marks a crucial advancement in this area, transforming the application of materials like adhesives, coatings, and lubricants. These systems elevate more than just precision; they boost efficiency, ensure consistency, and enhance control, leading to reduced waste and heightened productivity across diverse sectors, from aerospace to automotive.

As we witness the progression of automated fluid dispensing technology, it's clear we are moving towards fulfilling the rigorous demands for quality and precision that today's applications require. Through the integration of advanced robotics, state-of-the-art software, and meticulous engineering, these systems offer solutions previously considered beyond reach, guaranteeing that fluids are applied with exceptional accuracy.