The Leader In

Fluid Application Solutions

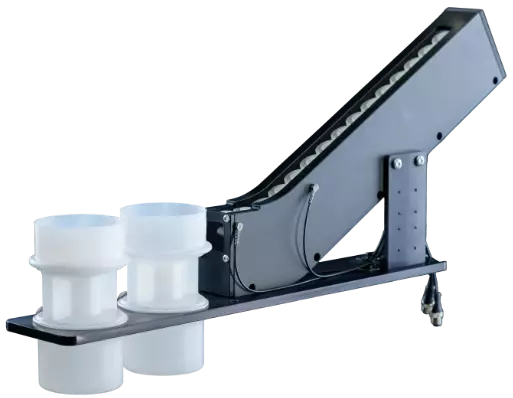

At Designetics, we pioneer precision and innovation in fluid dispensing equipment and systems. Serving a global clientele, our comprehensive range of products guarantees unmatched accuracy and efficiency for all your dispensing needs.

What Our Customers Are Saying

We take pride in our unparalleled service and cutting-edge solutions, but don’t just take our word for it. Hear directly from our satisfied customers about their experience with us.

Why Choose Designetics for Your Fluid Dispensing Needs

When it comes to fluid dispensing, Designetics is more than just a manufacturer. We are partners in innovation, creating solutions that are tailored to meet your specific needs. With a legacy of quality and a commitment to research and development, our products set industry standards.

Whether it’s our state-of-the-art manufacturing processes or our dedicated customer support, every aspect of our business is designed to offer you the best.

Application-Based Solutions

Catering to diverse industries, our fluid dispensing solutions are specifically designed to align with unique operational needs, ensuring optimal performance.

Applicator Prototyping

Turning concepts into reality, our rapid prototyping services bring your custom applicator designs to life with precision.

Personal Attention

Every client is unique, and at Designetics, you receive personalized attention ensuring your specific needs are always met.

The Designetics Blog

View AllStay updated with the latest in fluid dispensing technology, industry news, and more on the Designetics Blog.

Enhancing Precision with Automated Fluid Dispensing Systems

In the manufacturing and production landscape, achieving precision in fluid dispensing processes is fundamental for securing high-quality results across industries. The advent of automated fluid dispensing systems marks a crucial advancement in this area, transforming the application of materials like adhesives, coatings, and lubricants. These systems elevate more than just precision; they boost efficiency, ensure consistency, and enhance control, leading to reduced waste and heightened productivity across diverse sectors, from aerospace to automotive.

As we witness the progression of automated fluid dispensing technology, it's clear we are moving towards fulfilling the rigorous demands for quality and precision that today's applications require. Through the integration of advanced robotics, state-of-the-art software, and meticulous engineering, these systems offer solutions previously considered beyond reach, guaranteeing that fluids are applied with exceptional accuracy.

5 Ways Fluid Dispensing Systems Enhance Glass Assembly

In the dynamic manufacturing landscape, glass assembly processes have seen a significant evolution, demanding innovations that elevate efficiency, precision, and the overall quality of products. Central to this advancement are fluid dispensing systems, which have become indispensable in glass assembly applications. These systems excel in delivering unmatched precision, minimizing waste, and ensuring that products meet the highest quality standards. This article details five essential ways fluid dispensing systems have revolutionized glass assembly, highlighting their impact on modern manufacturing techniques.

Choosing the Right Fluid Dispensing System for Your Industry

In the complex world of manufacturing and production, the right tools can make all the difference in efficiency, quality, and profitability. Among these, fluid dispensing systems play a pivotal role across a vast array of industries, from automotive to aerospace, medical devices, and beyond. Choosing a system that aligns with your specific industry and production needs isn’t just advisable; it’s essential.

The wrong choice can lead to inefficiencies, increased costs, and product failures, while the right system can enhance production accuracy, reduce waste, and improve product quality. As we explore the critical considerations for selecting a fluid dispensing system, remember that the goal is to find a solution that fits seamlessly into your production line, ensuring optimal performance and longevity.